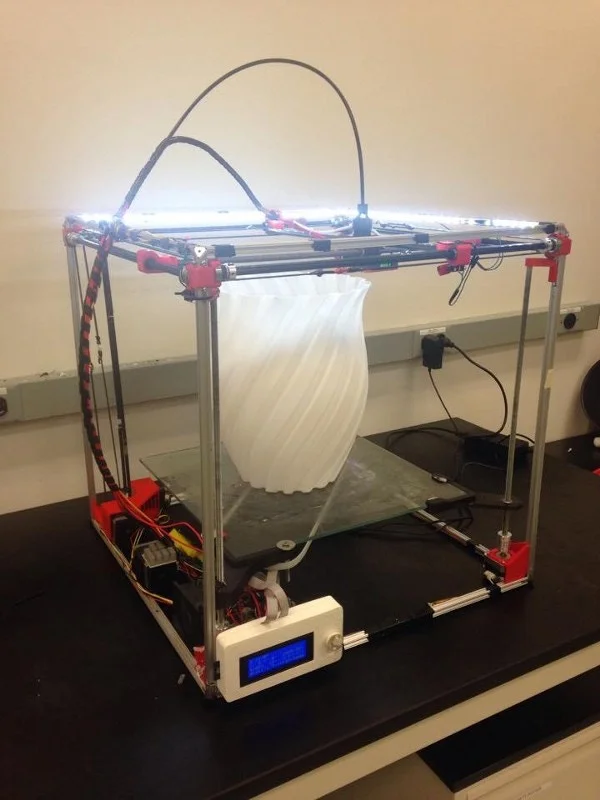

Readybox 3D Printer

Readybox was built to fix issues found on nearly all consumer-grade 3D Printers.

The Product

The machine was initially designed as a solution to the problems encountered while I managed the University of Maryland’s 3D Printing Lab.

The lab’s 40+ 3D printers would each require weekly if not daily maintenance, and when prints were completed there were almost always errors of some type. However, the biggest problem was the incredibly slow speed; it would often take more than a day to finish a single mid-sized print.

The Challenge: Optimization

My goal was to build a printer that would be a joy to use, so I combined all my ideas for improvement into one optimized machine. I wanted my machine to be faster, more accurate, and lower-maintenance than any other 3D printer.

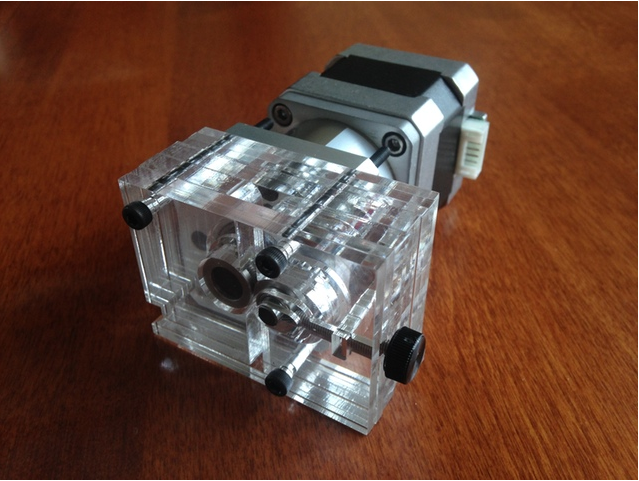

I built and patented a custom extruder design that could output more than 6 times faster than the leading 3D printer brands. A low-friction movement system and a next-gen 32 bit ARM controller board were added so that there would be nothing holding back the printer’s accuracy, and then the build area was expanded to a whopping 13”x13”x13” even though the printer’s size remained only 21”x21”x21.5”.

Jump-start

I initially designed Readybox as a personal challenge, but it soon became apparent was that people were interested in purchasing one for themselves. After a successful kickstarter campaign, units were manufactured in-house for over a year before I decided to go back to school to finish my mechanical engineering degree.

The development still continued in a minor way after the company was closed, and in 2016 I received the Leidos M-CERSI Undergraduate Research award for the application of my high-flow extruder design in a new medical 3D printer.